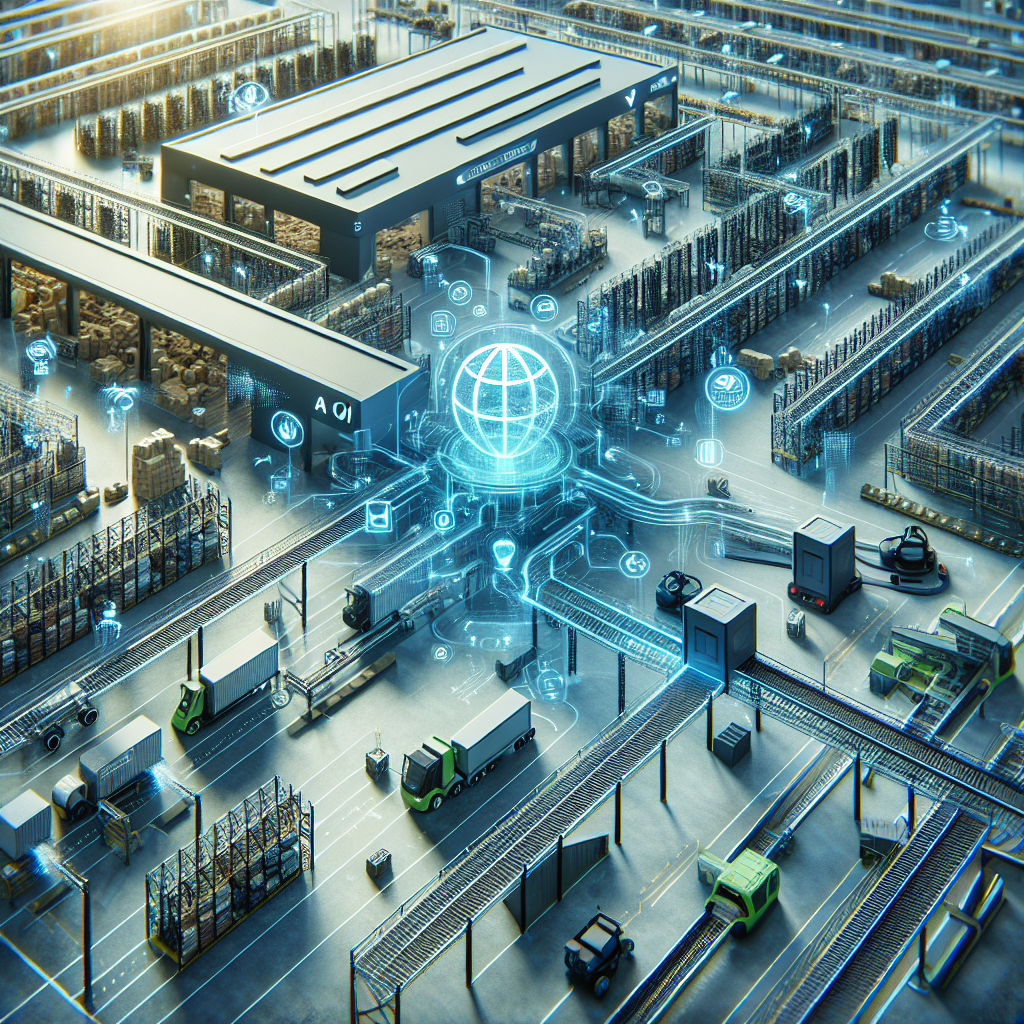

The Role of AI in Supply Chain Management

In recent years, Artificial Intelligence (AI) has emerged as a transformative force in supply chain management, offering a suite of tools that enhance efficiency and sustainability. AI technologies are increasingly utilized to optimize various components of the supply chain, from demand forecasting to inventory management. By leveraging machine learning algorithms and predictive analytics, businesses can anticipate market trends, reduce costs, and minimize waste. These capabilities not only improve operational efficiency but also contribute to a more sustainable supply chain by lowering energy consumption and reducing carbon emissions.

One of the key areas where AI is making a significant impact is in predictive analytics. By analyzing historical data, AI systems can predict future demand with remarkable accuracy. This helps companies maintain optimal inventory levels, reducing the risk of overproduction and waste. The implementation of AI-driven predictive analytics allows for a more responsive supply chain that can adapt quickly to changes in consumer demand. This adaptability is crucial for reducing the environmental impact of overstocking and understocking, contributing to a more sustainable supply chain.

Furthermore, AI is instrumental in enhancing logistics and transportation. With the help of AI, companies can optimize delivery routes, improving fuel efficiency and reducing emissions. AI algorithms analyze traffic patterns and weather conditions to determine the most efficient paths for transportation. This not only ensures timely deliveries but also lowers the carbon footprint of logistics operations. The integration of AI in logistics is a vital step towards achieving sustainability goals, as it enables companies to streamline operations while minimizing environmental impact.

AI is also playing a crucial role in promoting transparent and ethical supply chains. By utilizing AI-powered tools, companies can track and monitor their supply chain activities in real-time. This visibility helps ensure compliance with environmental regulations and ethical standards. AI can also identify potential risks and bottlenecks in the supply chain, allowing companies to address these issues proactively. As a result, AI not only optimizes supply chain operations but also helps build trust and accountability, reinforcing the commitment to sustainability.

Sustainability Challenges in Supply Chains

The modern supply chain faces a myriad of sustainability challenges that require innovative solutions to address. One of the primary challenges is the reduction of carbon emissions, which is crucial as transportation and logistics account for a significant portion of global greenhouse gas emissions. Companies are under increasing pressure to minimize their environmental impact while maintaining efficiency and profitability.

Another critical challenge is the efficient use of resources. Many supply chains suffer from wasteful practices, leading to excessive resource consumption and increased waste. Addressing these inefficiencies is essential for achieving sustainability goals. Companies must find ways to optimize their operations to reduce waste, which can be accomplished through improved inventory management and streamlined logistics.

The table below highlights some key sustainability challenges and their potential impacts on supply chain operations:

| Sustainability Challenge | Impact on Supply Chain |

|---|---|

| Carbon Emissions | Increased regulatory pressure and potential penalties. |

| Resource Efficiency | Higher operational costs due to waste and inefficiency. |

| Supply Chain Transparency | Difficulty in tracking and ensuring sustainable practices across the entire chain. |

Moreover, supply chain transparency remains a significant hurdle. Consumers and stakeholders are demanding more information about the origins and sustainability of products. This demand for transparency necessitates robust tracking and reporting mechanisms, which are often complex and costly to implement.

To navigate these challenges, companies are increasingly turning to artificial intelligence and data analytics. These technologies provide powerful tools to analyze vast amounts of data, enabling more informed decision-making and fostering more sustainable practices throughout the supply chain.

AI-Driven Optimization Techniques

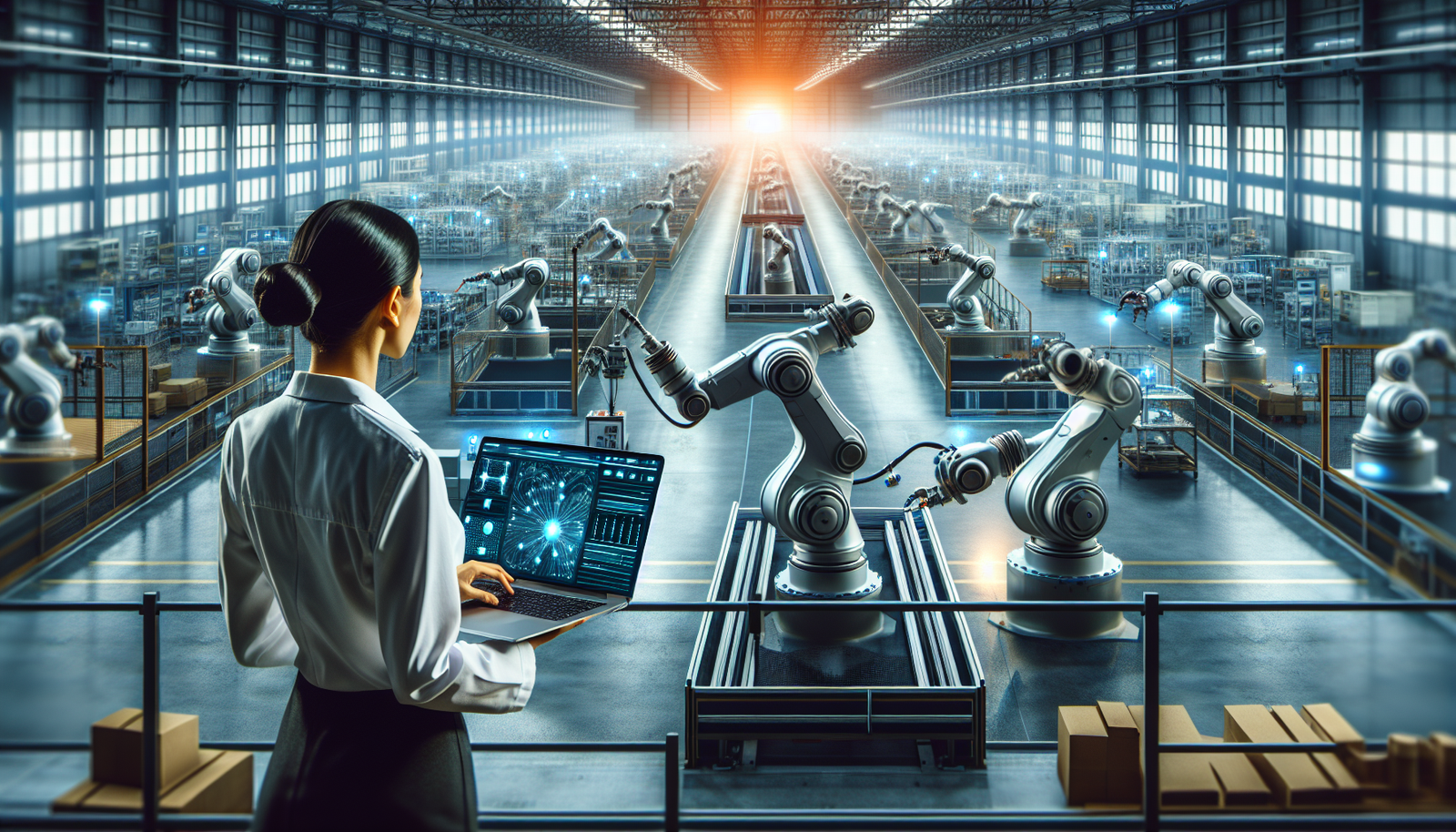

Artificial Intelligence (AI) is at the forefront of revolutionizing supply chain optimization by providing advanced techniques that enhance efficiency and sustainability. Companies are increasingly turning to AI-driven solutions to address the complexities of supply chain management. These techniques are not only improving operational processes but also significantly reducing environmental impact.

One of the most significant contributions of AI in supply chain optimization is through predictive analytics. By analyzing historical data and identifying patterns, AI systems can predict demand fluctuations, optimize inventory levels, and reduce waste. This predictive capability allows businesses to make informed decisions, ensuring that they can meet customer demands without overproducing or understocking. The result is a more streamlined and sustainable supply chain.

| Technique | Benefits |

|---|---|

| Predictive Analytics | Improves demand forecasting, reduces inventory waste |

| Machine Learning Algorithms | Enhances route optimization, reduces transportation emissions |

Another critical area where AI is making an impact is in route optimization. Machine learning algorithms can analyze various factors such as traffic patterns, weather conditions, and fuel costs to determine the most efficient delivery routes. By optimizing these routes, companies can significantly reduce their carbon footprint and operational costs. This not only contributes to environmental sustainability but also improves the overall efficiency of the supply chain.

- Reduces transportation emissions

- Enhances efficiency in logistics

- Contributes to cost savings

Predictive Analytics for Resource Efficiency

Predictive analytics plays a pivotal role in enhancing resource efficiency within supply chains. By leveraging advanced algorithms and machine learning models, businesses can forecast demand with greater accuracy, minimizing waste and optimizing inventory levels. Predictive models analyze historical data and identify patterns that help in anticipating future trends. This not only helps in reducing excess inventory but also ensures that resources are allocated efficiently, ultimately contributing to a more sustainable supply chain.

One of the significant benefits of predictive analytics is its ability to reduce a supply chain’s carbon footprint. By accurately predicting demand, companies can optimize transportation routes, leading to decreased fuel consumption and emissions. For instance, a study showed that companies utilizing predictive analytics in their logistics operations experienced a reduction in transportation costs by up to 15%. This optimization also extends to energy usage within warehouses, where predictive models can determine the most efficient ways to store and retrieve products, conserving energy and reducing operational costs.

Furthermore, predictive analytics enhances decision-making processes by providing insights into supplier performance and risks. Companies can create models that anticipate disruptions in the supply chain, such as those caused by natural disasters or geopolitical factors, allowing them to proactively manage and mitigate risks. This capability is particularly crucial in maintaining a resilient and sustainable supply chain. A survey indicated that supply chain disruptions could be reduced by 30% when predictive analytics are effectively implemented.

The implementation of predictive analytics in supply chains is facilitated by various data visualization tools that help in interpreting complex data sets. Data visualizations such as heatmaps, trend lines, and bar graphs enable stakeholders to identify bottlenecks and areas for improvement rapidly. These visual tools are essential for communicating insights across different levels of an organization, ensuring that all stakeholders are aligned in their efforts to optimize resource efficiency and drive sustainability.

Reducing Carbon Footprint with AI

Artificial Intelligence (AI) is playing a pivotal role in reducing the carbon footprint of supply chains by enhancing efficiency and promoting sustainable practices. Through the use of predictive analytics and advanced algorithms, AI provides companies with the ability to anticipate demand fluctuations, optimize routes, and streamline operations. By minimizing excess inventory and optimizing transportation networks, businesses can significantly cut down on emissions.

AI technologies enable real-time data analysis that helps in identifying inefficiencies and areas with high carbon outputs. For instance, AI can analyze data from IoT sensors installed in vehicles and warehouses to suggest optimal delivery routes and load planning strategies. These technologies not only contribute to the reduction of fuel consumption but also help in lowering greenhouse gas emissions. According to a recent study, companies leveraging AI for route optimization have witnessed a 15% reduction in fuel usage on average.

Moreover, AI-driven systems are pivotal in enhancing energy efficiency within production facilities. By using AI to monitor and control energy consumption, companies can achieve considerable reductions in their carbon footprint. AI applications can proactively manage energy usage patterns, adjust machinery operations during peak and off-peak hours, and suggest the adoption of renewable energy sources when feasible. The following table illustrates the impact of AI on energy consumption in various sectors:

| Sector | Reduction in Energy Consumption (%) |

|---|---|

| Manufacturing | 20% |

| Transportation | 15% |

| Retail | 10% |

The integration of AI in supply chains not only focuses on achieving sustainability goals but also provides a competitive edge by enhancing operational efficiency and reducing costs associated with energy and waste. As companies strive to meet regulatory requirements and consumer demands for sustainability, AI offers a robust solution to mitigate environmental impact while ensuring business profitability.

AI and Circular Economy in Supply Chains

The integration of AI into the circular economy model within supply chains is becoming increasingly significant. This approach not only enhances sustainability but also drives economic value by minimizing waste and maximizing resource efficiency. AI technologies facilitate the transition to a circular economy by optimizing processes such as recycling, refurbishing, and remanufacturing. They enable companies to predict material flows, optimize inventory management, and reduce waste generation.

One of the key areas where AI impacts the circular economy is through predictive analytics. By analyzing historical data and current market trends, AI algorithms can forecast demand with greater accuracy, ensuring that production aligns closely with consumption patterns. This reduces overproduction and the risk of excess inventory, which often leads to waste. Additionally, AI can identify the best times to recycle or refurbish products, extending their lifecycle and reducing the need for new raw materials.

Moreover, AI plays a crucial role in enhancing the traceability of materials within the supply chain. Through advanced data analytics, companies can track the journey of materials from production to end-of-life. This traceability ensures that materials are reused and recycled efficiently, supporting the circular economy. A deeper understanding of material flows is illustrated in the following table:

| Material Type | Recycling Rate (%) | Potential for Reuse (%) |

|---|---|---|

| Metals | 75 | 60 |

| Plastics | 30 | 50 |

| Textiles | 20 | 40 |

These data points demonstrate the potential for AI-driven improvements in recycling and reuse rates across various materials. By leveraging AI, companies can not only enhance their sustainability profiles but also realize cost savings and new revenue streams, thus revolutionizing supply chains in line with circular economy principles.

Real-time Monitoring and AI

Real-time monitoring in supply chains has become increasingly crucial as businesses strive to enhance sustainability. AI technologies play a significant role in enabling this real-time oversight by processing vast amounts of data swiftly and accurately. Companies can now track their supply chain processes with greater precision, identifying inefficiencies and areas for improvement more rapidly than ever before. This capability not only helps in reducing waste but also ensures that resources are utilized optimally, aligning with sustainability goals.

One of the primary benefits of AI in real-time monitoring is its ability to provide predictive insights. Using predictive analytics, companies can foresee potential disruptions in the supply chain and mitigate them before they escalate. For example, AI models can predict demand fluctuations by analyzing historical data and external factors such as market trends and seasonal variations. This allows businesses to adjust their procurement and production schedules accordingly, reducing excess inventory and minimizing environmental impact.

Furthermore, AI technologies facilitate carbon footprint reduction through enhanced monitoring capabilities. By analyzing data from various stages of the supply chain, AI can pinpoint areas with high carbon emissions. Companies can then implement targeted strategies to reduce their environmental impact. For instance, AI can suggest more efficient transportation routes or recommend alternative materials with a lower carbon footprint. This focus on carbon reduction is becoming increasingly important as businesses aim to meet global sustainability standards.

The integration of AI into supply chain monitoring also opens up potential for innovation and future trends. As AI technology continues to evolve, new applications and tools will emerge, offering even more sophisticated solutions for sustainability challenges. Businesses that adopt these technologies early will be better positioned to lead in sustainable supply chain management, reaping benefits such as improved efficiency, cost savings, and enhanced reputation.

AI in Supplier Selection and Evaluation

Artificial Intelligence (AI) is playing an increasingly pivotal role in enhancing the supplier selection and evaluation process, a crucial component of sustainable supply chain management. Traditional methods often rely on subjective assessments and limited data, which can lead to inefficiencies and unsustainable choices. AI, however, offers a data-driven approach that not only streamlines the process but also aligns it with sustainability goals.

One of the significant advantages of using AI in supplier selection is its capacity for predictive analytics. By analyzing vast amounts of data from various sources, AI can predict supplier performance and potential risks. This allows companies to choose suppliers that are not only cost-effective but also environmentally responsible. Moreover, AI algorithms can evaluate suppliers based on a range of factors including carbon emissions, resource usage, and waste management, ensuring that sustainability is a key criterion in supplier evaluation.

The integration of AI in this process can be visualized through a multi-step evaluation framework:

- Data Collection: Gathering information on supplier performance, sustainability practices, and compliance records.

- Analysis: Utilizing AI to process and analyze data, identifying patterns and potential risks.

- Scoring: Assigning scores to suppliers based on sustainability metrics and performance indicators.

- Selection: Choosing suppliers that meet predefined sustainability criteria and business needs.

AI not only aids in selecting suppliers but also in their ongoing evaluation. Continuous monitoring enabled by AI can provide real-time insights into supplier practices and performance. This ongoing assessment ensures that suppliers remain aligned with a company’s sustainability goals, adapting to new regulations and market demands. Furthermore, AI can facilitate better collaboration with suppliers by identifying areas for improvement and innovation, ultimately leading to more resilient and sustainable supply chains.

AI for Demand Forecasting and Inventory Management

Demand forecasting is a critical aspect of supply chain management, and AI is playing a transformative role in enhancing its accuracy and efficiency. By leveraging predictive analytics and machine learning algorithms, AI systems can analyze vast amounts of historical data, identifying patterns and trends that human analysts might overlook. This capability allows businesses to anticipate customer demand with greater precision, reducing the risk of overproduction or stockouts.

An essential component of AI-powered demand forecasting is the integration of real-time data sources, such as social media trends, weather forecasts, and economic indicators. By continuously updating forecasts based on the latest information, AI systems help companies maintain optimal inventory levels. This dynamic approach not only minimizes waste but also enhances customer satisfaction by ensuring product availability.

In the realm of inventory management, AI facilitates the automation of various processes, leading to improved efficiency and cost savings. For instance, AI-driven systems can optimize reorder points and quantities by considering multiple variables, including lead times, demand variability, and supply chain disruptions. This smart approach to inventory management helps in maintaining a delicate balance between holding costs and service levels.

Moreover, AI applications in inventory management often involve the use of data visualization tools to provide insights into inventory status and performance. These tools present complex data in an accessible format, enabling supply chain managers to make informed decisions quickly. Through interactive dashboards and charts, stakeholders can monitor key metrics, such as inventory turnover rates and carrying costs, ultimately driving more sustainable and responsive supply chain operations.

Enhancing Transportation Efficiency with AI

Artificial intelligence (AI) is increasingly being leveraged to enhance transportation efficiency within supply chains, offering significant opportunities for sustainability improvements. Through AI-driven solutions, companies are able to optimize routing, reduce fuel consumption, and minimize environmental impact. For example, AI algorithms can analyze vast amounts of data to determine the most efficient delivery routes, taking into account factors such as traffic patterns, weather conditions, and fuel costs. This not only reduces the carbon footprint of transportation activities but also leads to cost savings for businesses.

Moreover, AI technologies enable predictive maintenance of transportation fleets, which is crucial for sustainability. By analyzing data from vehicle sensors and historical maintenance records, AI can predict potential breakdowns and schedule maintenance before they occur. This proactive approach reduces the downtime of vehicles and ensures that the fleet operates at maximum efficiency. In turn, it reduces the need for emergency repairs and extends the lifespan of vehicles, contributing to a more sustainable supply chain.

Another critical aspect of AI in transportation is its role in facilitating the use of alternative energy sources. AI can optimize the deployment of electric and hybrid vehicles by determining the best routes and times for recharging, thus overcoming one of the main barriers to the adoption of clean energy in transportation. This strategic use of AI not only supports a reduction in the reliance on fossil fuels but also aligns with global efforts to combat climate change.

The following table illustrates the potential benefits of AI in transportation efficiency:

| AI Application | Benefit | Impact on Sustainability |

|---|---|---|

| Route Optimization | Reduced Fuel Consumption | Lower Carbon Emissions |

| Predictive Maintenance | Decreased Vehicle Downtime | Extended Vehicle Lifespan |

| Alternative Energy Optimization | Efficient Energy Use | Reduced Fossil Fuel Dependence |

AI’s Role in Waste Reduction

Artificial Intelligence (AI) is pivotal in reducing waste within supply chains, offering innovative solutions that enhance efficiency and promote sustainability. By leveraging AI technologies, companies can significantly minimize excess inventory, decrease energy consumption, and lower carbon emissions. This not only helps in cutting costs but also aligns with global sustainability goals.

One of the primary ways AI contributes to waste reduction is through predictive analytics. Predictive analytics uses historical data to forecast future trends, enabling supply chain managers to make informed decisions about inventory levels and production schedules. This preemptive approach helps in avoiding overproduction and minimizing waste. For instance, AI can predict demand fluctuations and adjust orders accordingly, ensuring that products are manufactured in quantities that match actual consumer demand.

Moreover, AI technologies enable real-time monitoring and analysis of supply chain processes. This capability allows for the immediate identification and rectification of inefficiencies, such as bottlenecks or delays, thereby reducing waste. By introducing AI-driven automation, companies can streamline operations, leading to a more efficient use of resources. The following table illustrates the impact of AI on waste reduction in various supply chain activities:

| Supply Chain Activity | Traditional Waste Levels | Waste Levels with AI Implementation |

|---|---|---|

| Inventory Management | 20% | 5% |

| Production Planning | 15% | 3% |

| Transportation | 12% | 4% |

In conclusion, AI’s role in waste reduction is transformative and far-reaching. By integrating AI into supply chain operations, businesses can achieve significant reductions in waste and enhance their overall sustainability. As AI technology continues to evolve, its potential to further optimize supply chains and reduce environmental impact will only grow, making it an indispensable tool for future-focused companies.

Case Studies of AI Implementation

In recent years, numerous organizations have successfully integrated AI into their supply chain operations to enhance sustainability. Company A, a global leader in consumer electronics, has utilized AI-driven predictive analytics to optimize their logistics network. By leveraging machine learning algorithms, they have significantly reduced fuel consumption and transportation costs. This optimization has not only improved their delivery efficiency but also decreased their carbon emissions by 15% over the past two years.

Another compelling example is Company B, a major player in the fashion industry, which has employed AI to manage inventory more effectively. Through the implementation of AI-based demand forecasting models, they have achieved a 20% reduction in overproduction. This reduction not only minimizes waste but also helps in conserving resources such as water and energy used in garment production. The table below illustrates the environmental impact before and after AI implementation:

| Metric | Before AI Implementation | After AI Implementation |

|---|---|---|

| Overproduction (units) | 500,000 | 400,000 |

| Water Usage (gallons) | 2,000,000 | 1,600,000 |

| Energy Consumption (kWh) | 1,000,000 | 800,000 |

Furthermore, Company C, a logistics provider, has implemented AI-powered route optimization tools to streamline their delivery processes. By analyzing traffic patterns and weather conditions in real-time, these tools have enabled more efficient routing, leading to a 25% reduction in delivery times. This improvement not only boosts customer satisfaction but also contributes to lower fuel consumption, further supporting sustainability goals.

These case studies highlight the diverse applications of AI in making supply chains more sustainable. By adopting innovative AI technologies, companies can significantly reduce their environmental impact while achieving operational efficiencies. As these examples demonstrate, the integration of AI into supply chain management is not just a theoretical concept but a practical solution with tangible benefits.

Future Trends in AI and Sustainable Supply Chains

As we look towards the future, the integration of Artificial Intelligence (AI) in sustainable supply chains is set to become even more sophisticated and impactful. Predictive analytics will continue to evolve, providing companies with unprecedented insights into demand forecasting, inventory management, and logistics optimization. This will enable businesses to not only reduce waste but also minimize their carbon footprint, aligning with global sustainability goals.

One of the key trends is the increasing use of AI-powered automation in supply chain processes. Automated systems, driven by AI, will streamline operations such as order processing, shipment tracking, and customer service. This transition is expected to lead to significant cost savings and efficiency improvements. Furthermore, AI-driven automation can contribute to sustainability by optimizing resource usage and reducing energy consumption.

The future will also see the rise of collaborative AI platforms that bring together various stakeholders in the supply chain ecosystem. These platforms will facilitate real-time data sharing and decision-making, fostering a more integrated and transparent supply chain network. Such collaboration will be crucial in tackling complex sustainability challenges, as it allows for more coordinated and effective responses.

Finally, the development of AI-driven sustainability metrics and reporting tools will become increasingly important. These tools will enable companies to accurately measure and report their sustainability performance, providing stakeholders with clear insights into their environmental impact. The adoption of standardized metrics will also promote accountability and encourage more companies to adopt sustainable practices.