The Role of AI in 3D Printing

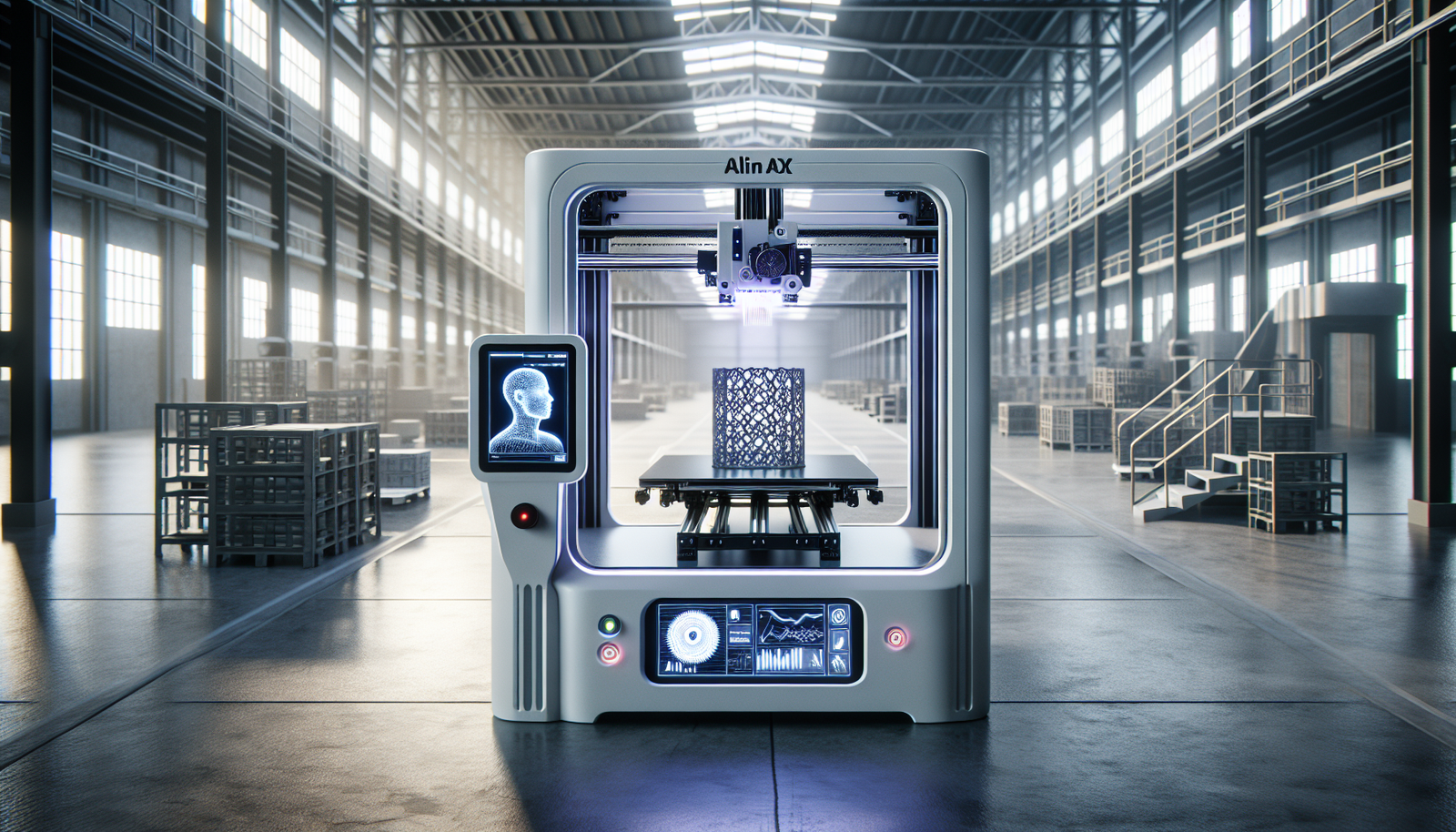

The integration of Artificial Intelligence (AI) into 3D printing technology is significantly transforming the landscape of manufacturing, making it more sustainable and efficient. AI plays a crucial role in optimizing design processes, which is fundamental for achieving eco-friendly production. By utilizing AI algorithms, manufacturers can intelligently design complex structures that require less material without compromising strength or functionality. This not only reduces material costs but also minimizes waste, which is critical for sustainable practices.

AI-driven 3D printing also enhances energy efficiency. Traditional 3D printing processes can be energy-intensive, but AI can predict and adjust energy usage in real-time during the printing process. This capability allows for smarter energy consumption, reducing the overall carbon footprint of manufacturing. An important aspect of this is the use of AI to manage and optimize the printing paths, leading to faster production times and lower energy requirements.

Moreover, AI contributes to quality control and predictive maintenance in 3D printing. By analyzing data from sensors and cameras, AI systems can detect anomalies and defects in real-time, ensuring high-quality outputs. This proactive approach not only reduces waste from faulty products but also extends the lifespan of 3D printing equipment by predicting maintenance needs before failures occur.

The table below illustrates some key benefits of AI in 3D printing:

| Benefit | Description |

|---|---|

| Material Optimization | Reduces material usage and waste through intelligent design algorithms. |

| Energy Efficiency | Optimizes energy consumption, lowering the carbon footprint. |

| Quality Control | Ensures high-quality outputs by detecting defects in real-time. |

| Predictive Maintenance | Extends equipment lifespan by anticipating maintenance needs. |

Sustainable Materials in 3D Printing

The integration of sustainable materials in 3D printing is a pivotal aspect of creating an eco-friendly manufacturing environment. Traditional manufacturing often relies on materials that are either non-renewable or difficult to recycle, contributing to environmental degradation. In contrast, 3D printing leverages a variety of eco-friendly materials that significantly reduce the ecological footprint. These materials range from biodegradable plastics to recycled composites, each offering unique benefits in terms of sustainability and performance.

One of the most promising materials is PLA (Polylactic Acid), a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. PLA is widely used in 3D printing due to its ease of use and low environmental impact. Another innovative material is recycled PET (Polyethylene Terephthalate), which repurposes plastic waste into new products, promoting a circular economy. Additionally, natural fiber composites, such as those reinforced with wood or hemp fibers, are gaining traction for their strength and reduced carbon footprint.

Beyond individual materials, the development of composite materials has opened new avenues for sustainable 3D printing. These composites often combine traditional plastics with natural fibers, enhancing material properties while reducing reliance on non-renewable resources. For instance, wood-plastic composites offer a sustainable alternative for producing durable and aesthetically pleasing objects. The table below illustrates some common sustainable materials used in 3D printing and their key characteristics:

| Material | Source | Benefits |

|---|---|---|

| PLA | Renewable resources (corn, sugarcane) | Biodegradable, low environmental impact |

| Recycled PET | Recycled plastic bottles | Promotes circular economy, reduces waste |

| Wood-Plastic Composite | Wood fibers, recycled plastic | Durable, aesthetically pleasing |

The use of sustainable materials in 3D printing not only reduces waste and energy consumption but also encourages innovation in material science. As the industry continues to evolve, the potential for developing new sustainable materials is vast, paving the way for a greener manufacturing future. By prioritizing the use of these materials, manufacturers can significantly reduce their environmental impact while meeting the growing demand for sustainable products.

Energy Efficiency Through AI

Artificial Intelligence (AI) plays a critical role in enhancing the energy efficiency of 3D printing processes, thereby contributing to more sustainable manufacturing practices. By leveraging AI algorithms, manufacturers can optimize the energy consumption of 3D printers, ensuring that each print uses the minimal amount of energy necessary without compromising on quality. This optimization is achieved through AI’s ability to analyze data in real-time and make adjustments to printing parameters such as speed, layer height, and material flow, resulting in significant energy savings.

One of the key ways AI enhances energy efficiency is through predictive maintenance. By continuously monitoring the performance of 3D printers, AI can predict when a machine is likely to fail or require maintenance, thereby avoiding unexpected breakdowns that consume additional energy. Regular and timely maintenance ensures that machines operate at peak efficiency, reducing energy waste. Furthermore, AI-driven analysis can suggest more energy-efficient printing paths and techniques, which can be automatically implemented to further reduce energy consumption.

| AI Technique | Energy Saving (%) | Description |

|---|---|---|

| Predictive Maintenance | 15% | Reduces energy waste by preventing unexpected machine breakdowns. |

| Real-time Parameter Optimization | 20% | Adjusts printing parameters dynamically to minimize energy use. |

| Efficient Printing Paths | 10% | Optimizes the route of the print head to reduce unnecessary movements. |

In conclusion, the integration of AI technologies into 3D printing not only improves the energy efficiency of the printing process but also contributes to the broader goal of sustainable manufacturing. As AI continues to evolve, its applications in 3D printing are likely to expand, offering even more opportunities for energy savings and environmental benefits. By reducing energy consumption, manufacturers can lower their carbon footprint and contribute to a greener world, aligning with global efforts to combat climate change.

Waste Reduction and Recycling

Waste reduction is a key component of creating a sustainable future, and AI-driven 3D printing plays a significant role in this endeavor. By utilizing AI algorithms, manufacturers can optimize 3D printing processes to minimize material usage. These algorithms analyze and predict the most efficient way to construct an object, effectively reducing excess material. In fact, studies have shown that AI integration can result in a waste reduction of up to 30% compared to traditional methods.

Moreover, the incorporation of recycling processes within 3D printing further enhances waste reduction. The materials used in 3D printing, such as PLA and PETG, can often be recycled and reused in subsequent print jobs. This practice not only conserves resources but also supports a circular economy. A recent report indicates that approximately 50% of the materials used in 3D printing can be recycled, significantly lowering the environmental footprint of manufacturing processes.

| Year | Material Waste Reduction (%) | Recycled Material Usage (%) |

|---|---|---|

| 2020 | 20% | 30% |

| 2023 | 30% | 50% |

Implementing AI in 3D printing not only helps in reducing waste but also encourages the use of recycled materials. By strategically utilizing recycled materials, companies can achieve both economic and environmental benefits. This dual advantage is crucial as industries strive to meet stricter environmental regulations and consumer demand for sustainable products.

AI-Optimized Design for Sustainability

Artificial Intelligence (AI) plays a pivotal role in enhancing the sustainability of 3D printing by optimizing design processes to minimize material usage and waste. Through advanced algorithms, AI can analyze and refine complex geometries, ensuring that each design is both structurally sound and resource-efficient. This capability is especially critical in industries where material costs and environmental impact are significant concerns. By leveraging AI, manufacturers can create designs that not only meet but exceed traditional performance standards while using less material.

One significant advantage of AI-optimized design is the ability to conduct rapid iterations and simulations. This process allows for the exploration of a multitude of design variations, assessing their environmental impact and energy consumption. For instance, AI can simulate how different materials respond to stress and strain, identifying the most sustainable options for a given application. This not only reduces the trial-and-error phase but also ensures that the final product is optimized for both performance and sustainability.

Moreover, AI’s ability to integrate with data analytics enables the continuous improvement of design processes. By analyzing data from past projects, AI systems can identify patterns and insights that inform future design strategies. This iterative learning process leads to increasingly sustainable outcomes over time. For example, a design that initially used excessive support structures can be refined to reduce material use by analyzing previous data and adjusting the approach accordingly.

Incorporating AI into the design phase also allows for better collaboration across different teams involved in the manufacturing process. With AI-driven insights, designers, engineers, and sustainability experts can work together more effectively, ensuring that every aspect of the product lifecycle is considered and optimized for sustainability. This holistic approach not only enhances the eco-friendliness of products but also aligns with broader environmental goals and regulations.

Case Studies of Sustainable 3D Printing

In recent years, several companies have successfully implemented AI-driven sustainable 3D printing techniques, showcasing the potential of this technology in transforming manufacturing processes. By examining these case studies, we can gain insights into the practical applications and benefits of integrating AI with 3D printing for eco-friendly solutions. These examples highlight how businesses are not only optimizing their production lines but also significantly minimizing their environmental footprints.

One noteworthy case study involves a leading automotive manufacturer that adopted AI-enhanced 3D printing to produce lightweight vehicle components. This company utilized AI algorithms to analyze and optimize design structures, resulting in a 30% reduction in material usage. The implementation of these techniques not only decreased waste but also improved the fuel efficiency of their vehicles, contributing to lower carbon emissions. The table below outlines the key outcomes of this initiative:

| Aspect | Before Implementation | After Implementation |

|---|---|---|

| Material Usage | 100% | 70% |

| Waste Production | High | Reduced by 30% |

| Fuel Efficiency | Standard | Improved by 15% |

Another compelling example is from the construction industry, where a company leveraged AI and 3D printing to develop sustainable housing solutions. By employing predictive algorithms, they were able to optimize building designs for energy efficiency and structural integrity. This approach led to a 25% decrease in energy consumption during construction and a 40% reduction in construction waste. The benefits extended beyond the building phase, as the houses themselves demonstrated enhanced energy performance, leading to lower utility costs for residents. Below is a list of the primary advantages realized through this project:

- Significant reduction in energy consumption and waste during construction.

- Improved thermal insulation and energy efficiency of the finished structures.

- Cost savings for both the construction company and homeowners.

- Increased adoption of sustainable practices in the construction sector.

Challenges and Solutions in Eco-Friendly 3D Printing

Eco-friendly 3D printing faces several challenges that need to be addressed to fully realize its potential in sustainable manufacturing. One of the primary challenges is the reliance on traditional materials that are not biodegradable or recyclable. The vast majority of 3D printing materials, such as certain plastics, contribute to environmental pollution when not disposed of properly. Additionally, the energy consumption of 3D printers, especially during large-scale production, can be significant, negating some of the environmental benefits. Overcoming these challenges requires innovative solutions that incorporate both technological advancements and sustainable practices.

One solution to the material challenge is the development and use of bio-based and recyclable materials. Researchers are exploring materials such as bioplastics, which are derived from renewable sources and are biodegradable. To illustrate the effectiveness of these materials, consider the following comparison:

| Material Type | Biodegradability | Recyclability |

|---|---|---|

| Traditional Plastics | No | Limited |

| Bioplastics | Yes | Yes |

Another significant challenge is the optimization of energy usage during the 3D printing process. AI plays a crucial role in addressing this by optimizing design and manufacturing processes to reduce energy consumption. AI algorithms can analyze data to determine the most efficient printing paths and settings, thereby minimizing energy use. To tackle this, manufacturers can implement the following strategies:

- Utilizing AI-driven simulations to test and refine designs before actual printing.

- Employing energy-efficient 3D printers that are designed to consume less power.

- Implementing monitoring systems to track and optimize energy usage in real-time.

By addressing these challenges through innovative solutions, eco-friendly 3D printing can make significant strides towards becoming a cornerstone of sustainable manufacturing. The integration of AI not only enhances efficiency but also promotes the development of new materials and technologies that align with environmental goals. As the industry continues to evolve, ongoing research and collaboration will be essential to overcome existing hurdles and drive further advancements in sustainable 3D printing.

Future Trends in AI and 3D Printing

The integration of Artificial Intelligence (AI) with 3D printing is paving the way for transformative trends that promise to enhance sustainability in manufacturing. One of the most significant future trends is the development of AI algorithms that can dynamically optimize 3D printing processes. These algorithms can analyze a vast amount of data in real time to make precise adjustments, ensuring that material use is minimized and energy efficiency is maximized. This will not only reduce the carbon footprint of manufacturing but also lead to cost savings for producers, making eco-friendly manufacturing more accessible and appealing.

Another promising trend is the application of AI in predictive maintenance for 3D printers. By utilizing AI-driven analytics, manufacturers can anticipate equipment failures before they occur, significantly reducing downtime and waste. This predictive capability is crucial for maintaining the efficiency and longevity of 3D printers, which are often expensive investments. As AI technology advances, we can expect more sophisticated models that provide deeper insights into the operational status of printing equipment, thus ensuring continuous improvement in manufacturing processes.

Additionally, AI is expected to play a critical role in the customization and personalization of 3D-printed products. By leveraging AI, manufacturers can analyze consumer data to create highly personalized products with minimal waste, as the production process will be precisely tailored to individual needs and preferences. This trend not only supports sustainability by reducing excess production but also aligns with the growing demand for personalized products in various industries, including healthcare, automotive, and fashion.

The collaboration between AI and 3D printing is also set to revolutionize material innovation. AI can assist in the development of new, sustainable materials that are specifically designed for 3D printing processes. These materials will be optimized for strength, flexibility, and biodegradability, further enhancing the environmental benefits of 3D printing. As such, the future of AI-driven 3D printing holds great promise for creating a more sustainable and efficient manufacturing landscape.

Policy Implications and Industry Standards

The integration of AI-driven sustainable 3D printing into mainstream manufacturing poses significant policy implications. Governments and regulatory bodies are increasingly recognizing the potential of this technology to reduce environmental impact. Policies encouraging the adoption of AI-enhanced 3D printing can lead to substantial reductions in carbon emissions and material waste. For instance, implementing tax incentives for companies that invest in sustainable 3D printing technologies could accelerate the transition to eco-friendly manufacturing processes.

In addition to policy measures, industry standards are critical for ensuring that the benefits of AI in 3D printing are maximized. Establishing standards for material usage, energy consumption, and waste management can help create a unified framework that promotes sustainability. The development of global standards could facilitate cross-border collaborations and innovations, allowing for more efficient and sustainable production methods to be shared and adopted worldwide.

Moreover, collaboration between industry stakeholders and policymakers is essential to create effective regulations that support sustainable practices while fostering innovation. An analysis of existing policies can uncover gaps and areas for improvement, ensuring that regulations keep pace with technological advancements. This collaboration could also lead to the creation of certification systems for sustainable 3D printing practices, providing consumers with transparent information about the environmental impact of products they purchase.

Here is a simple breakdown of potential policy measures and industry standards:

- Implementation of tax incentives for sustainable technology adoption

- Development of standardized metrics for energy and material efficiency

- Creation of international certification systems for eco-friendly practices

| Policy Measures | Benefits |

|---|---|

| Tax incentives | Encourage investment in sustainable technology |

| Standardized metrics | Ensure consistent and measurable sustainability practices |

| Certification systems | Provide transparency and consumer assurance |

Collaborative Efforts for a Greener Future

Collaborative efforts between various stakeholders are essential in advancing the integration of AI in sustainable 3D printing. By bringing together manufacturers, researchers, policymakers, and environmental organizations, these collaborations aim to create a robust framework that supports eco-friendly manufacturing practices. Manufacturers play a crucial role by adopting AI-driven technologies that enhance production efficiency and minimize waste. Researchers contribute by developing innovative algorithms that optimize material usage and energy consumption. Meanwhile, policymakers focus on creating regulations and incentives that encourage the adoption of sustainable manufacturing technologies.

One of the key strategies in these collaborations is the formation of alliances and consortia that focus on shared goals for sustainability. These groups often conduct joint research and development projects to push the boundaries of what can be achieved with AI and 3D printing. For instance, an

- alliance of leading academic institutions

- 3D printing companies

- environmental NGOs

might work together to develop new biodegradable materials that can be used in 3D printing processes. These efforts not only contribute to the reduction of environmental impact but also pave the way for new applications of 3D printing in various industries.

Data sharing is another critical aspect of collaborative efforts. By creating platforms where data from various projects can be shared and analyzed, stakeholders can gain valuable insights into the effectiveness of different strategies and technologies. This collaborative approach is illustrated in the following table, which highlights some of the key focus areas and outcomes:

| Focus Area | Stakeholder Involvement | Outcomes |

|---|---|---|

| Material Optimization | Manufacturers, Researchers | Reduced Waste, Cost Savings |

| Energy Efficiency | Manufacturers, Policymakers | Lower Carbon Footprint |

| Regulatory Framework | Policymakers, Environmental Organizations | Incentives for Sustainable Practices |

These collaborative initiatives are crucial for fostering a culture of sustainability in the manufacturing sector. They provide a platform for continuous learning and adaptation, ensuring that the integration of AI in 3D printing remains aligned with the broader goals of environmental conservation and resource efficiency. As these partnerships evolve, they hold the potential to significantly reduce the carbon footprint of manufacturing processes and lead to a more sustainable future.