The Role of AI in Sustainable Manufacturing

Artificial Intelligence (AI) is rapidly becoming a cornerstone in the pursuit of sustainable manufacturing. By automating complex processes and providing real-time data analysis, AI enhances operational efficiency, which ultimately leads to reduced resource consumption and waste. AI-driven systems can predict equipment failures, optimize production schedules, and manage supply chains in a way that minimizes environmental impact. This level of precision allows manufacturers to operate with greater sustainability than traditional methods ever could.

One of the most significant contributions of AI is its ability to enhance energy efficiency. By analyzing consumption patterns, AI can suggest modifications that lead to substantial energy savings. For instance, AI can adjust machinery operations during off-peak energy hours or recommend maintenance schedules that ensure equipment runs at optimal efficiency. According to a recent study, factories employing AI technologies reported a 15% reduction in energy consumption compared to those relying solely on human oversight.

Moreover, AI supports sustainable manufacturing by enabling smart waste management. Through machine learning algorithms, AI systems can sort and categorize waste more accurately than human workers, leading to higher recycling rates and less landfill use. An example can be seen in AI-driven sorting systems that utilize optical sensors to differentiate materials, ensuring that recyclables are processed correctly. This technological advancement is crucial for promoting zero-waste initiatives in manufacturing plants.

The implementation of AI in eco-friendly practices extends to supply chain management as well. AI can track and analyze the environmental footprint of the entire supply chain, from raw material sourcing to product delivery. By identifying carbon-intensive processes or suppliers, manufacturers can make informed decisions to switch to greener alternatives. This strategic approach not only reduces emissions but also enhances brand reputation as consumers increasingly demand sustainable products.

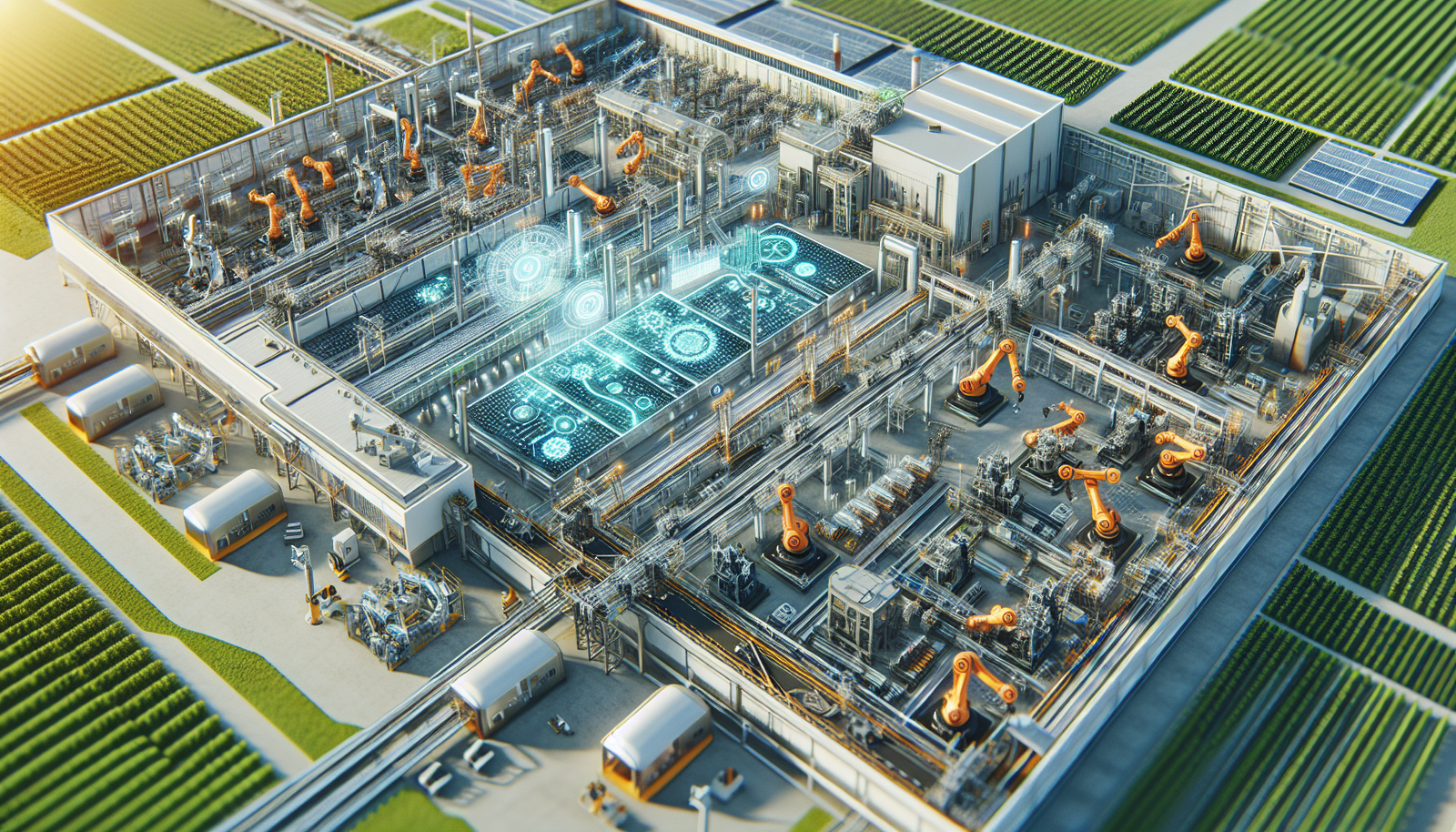

AI-Driven Efficiency in Production

Artificial Intelligence (AI) is at the forefront of revolutionizing production efficiency within the manufacturing sector. By integrating AI technologies, manufacturers can significantly streamline operations, leading to a reduction in energy consumption and material waste. One of the key areas where AI excels is in predictive maintenance. Through the use of machine learning algorithms, AI systems can predict equipment failures before they occur, allowing for timely maintenance and minimizing downtime. This proactive approach not only extends the life of machinery but also reduces the environmental impact associated with manufacturing disruptions.

Furthermore, AI enhances the decision-making process in production by analyzing vast amounts of data to optimize manufacturing workflows. For instance, AI can identify patterns and trends that human operators might overlook, ensuring that production lines operate at maximum efficiency. This data-driven approach allows for real-time adjustments in production schedules, adapting to demand fluctuations without compromising on sustainability goals. The integration of AI in production processes also facilitates the shift towards smart factories, where interconnected systems communicate seamlessly to enhance overall productivity.

| AI Application | Benefit |

|---|---|

| Predictive Maintenance | Reduces equipment downtime and extends machinery lifespan |

| Data-Driven Optimization | Enhances decision-making and production efficiency |

| Smart Factories | Promotes seamless communication between systems for improved productivity |

Moreover, AI’s role in enhancing production efficiency is complemented by its ability to foster sustainable practices through waste reduction. By implementing AI-driven quality control systems, manufacturers can detect defects early in the production cycle, minimizing the number of faulty products and reducing material wastage. These systems utilize computer vision and sensor data to maintain high-quality standards, ensuring that resources are utilized responsibly. In addition, AI algorithms can optimize resource allocation, ensuring that materials and energy are used only where necessary, thereby promoting a more sustainable manufacturing ecosystem.

- AI enhances equipment reliability through predictive maintenance.

- Data-driven insights lead to optimized production workflows.

- Quality control systems reduce waste by detecting defects early.

Reducing Waste with Predictive Analytics

Predictive analytics is a powerful tool in the realm of sustainable manufacturing, offering significant potential to minimize waste and optimize resource utilization. By leveraging data-driven insights, manufacturers can anticipate potential issues in the production process before they occur. This proactive approach allows for timely interventions that help in reducing material waste and enhancing overall efficiency. For instance, machine learning algorithms can analyze historical production data to predict equipment failures, enabling preemptive maintenance and preventing unnecessary downtime.

In addition to equipment maintenance, predictive analytics also plays a crucial role in inventory management. By accurately forecasting demand, manufacturers can optimize their inventory levels, ensuring that resources are neither overstocked nor underutilized. This balance not only reduces waste but also decreases storage costs and minimizes the environmental footprint associated with excess inventory. The following table illustrates the impact of predictive analytics on waste reduction across various manufacturing sectors:

| Industry Sector | Waste Reduction (%) | Cost Savings ($) |

|---|---|---|

| Automotive | 15 | 500,000 |

| Electronics | 20 | 750,000 |

| Textiles | 25 | 300,000 |

The integration of predictive analytics into manufacturing processes not only aids in waste reduction but also supports eco-friendly practices. By optimizing production schedules and reducing excess energy consumption, companies can lower their carbon footprint. Furthermore, the insights gained from predictive analytics can guide the development of more sustainable production techniques and materials. As industries continue to adopt these advanced technologies, the role of predictive analytics in fostering a greener future becomes increasingly evident.

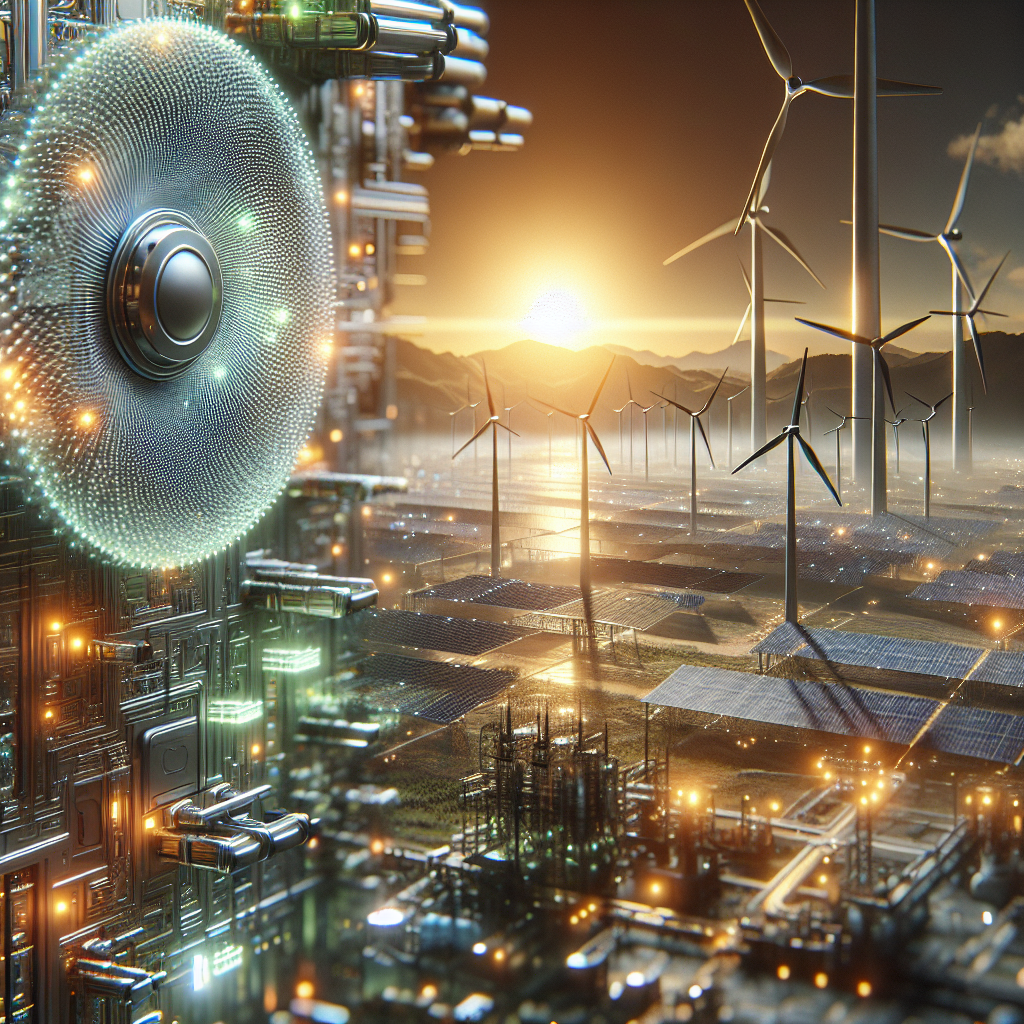

Energy Management and AI Innovations

Artificial Intelligence (AI) is playing a pivotal role in revolutionizing energy management within the manufacturing sector. By leveraging AI technologies, manufacturers can optimize energy consumption, leading to significant cost savings and reduced environmental impact. AI-driven systems analyze vast amounts of data in real-time to identify patterns and predict energy demand, allowing for more efficient energy distribution. This not only helps in minimizing energy waste but also supports the integration of renewable energy sources, making manufacturing processes more sustainable.

One of the key innovations in this domain is the implementation of smart grids powered by AI. These grids enable dynamic energy management by adjusting energy loads according to fluctuating demands, thus ensuring that energy is used efficiently. For instance, during peak production hours, AI algorithms can prioritize energy distribution to critical machinery, while during downtime, energy can be diverted to storage systems or other less intensive processes. This flexibility is crucial for maintaining a balance between energy supply and demand, ultimately reducing the carbon footprint of manufacturing facilities.

Furthermore, AI innovations extend to predictive maintenance, which plays a crucial role in energy management. By continuously monitoring equipment performance and predicting potential failures, AI systems can schedule maintenance activities proactively. This not only prevents unexpected machinery breakdowns but also ensures that machines operate at optimal efficiency, thereby conserving energy. Predictive maintenance has been shown to reduce energy consumption by up to 20%, contributing significantly to sustainability efforts.

The following table illustrates some of the benefits of AI-driven energy management in manufacturing:

| AI Innovation | Benefit |

|---|---|

| Smart Grids | Optimized energy distribution and integration of renewable sources |

| Predictive Maintenance | Reduced energy consumption and improved machine efficiency |

| Real-time Data Analysis | Enhanced decision-making and reduced energy waste |

In conclusion, the integration of AI in energy management is a transformative step towards achieving a greener future in manufacturing. By enhancing efficiency, reducing waste, and promoting eco-friendly practices, AI is not just a technological advancement but a crucial ally in the quest for sustainability.

AI in Supply Chain Optimization

Artificial Intelligence (AI) is playing a pivotal role in optimizing supply chains, a crucial component of sustainable manufacturing. The integration of AI technologies allows manufacturers to streamline operations, minimize waste, and reduce energy consumption. This optimization is achieved through advanced data analytics, predictive modeling, and real-time monitoring.

AI-driven supply chain optimization involves the use of algorithms to analyze vast amounts of data from various sources, including suppliers, manufacturers, and distributors. This analysis helps in identifying patterns and predicting potential disruptions, allowing companies to proactively address issues before they escalate. As a result, businesses can maintain a steady flow of materials and products, ensuring minimal resource wastage and reduced carbon footprints.

- Inventory Management: AI systems enhance inventory management by predicting demand fluctuations and optimizing stock levels. This leads to a significant reduction in excess inventory and associated waste.

- Transportation Efficiency: By analyzing traffic patterns and weather conditions, AI can optimize delivery routes, reducing fuel consumption and emissions.

- Supplier Collaboration: AI facilitates better communication and collaboration with suppliers, ensuring that sustainable practices are upheld throughout the supply chain.

Below is a table illustrating the impact of AI on supply chain efficiency:

| Aspect | Traditional Supply Chain | AI-Optimized Supply Chain |

|---|---|---|

| Lead Time | 5-7 days | 2-3 days |

| Inventory Levels | High | Optimal |

| Carbon Emissions | High | Reduced |

Ultimately, the adoption of AI in supply chain optimization not only enhances operational efficiency but also supports the broader goals of sustainable manufacturing. By reducing waste, lowering emissions, and promoting resource conservation, AI contributes to a greener future for the manufacturing industry.

Smart Maintenance for Equipment Longevity

In the realm of sustainable manufacturing, smart maintenance plays a pivotal role in extending the life of equipment, thereby reducing the need for frequent replacements and minimizing environmental impact. By leveraging artificial intelligence (AI), manufacturers can shift from traditional maintenance strategies to predictive maintenance models. This transition allows for real-time monitoring and analysis of equipment performance, identifying potential failures before they occur. A study by McKinsey & Company indicates that AI-driven predictive maintenance can reduce machine downtime by up to 50% and increase machine life by 20% to 40%.

Implementing AI in maintenance involves the use of advanced sensors and data analytics to continuously assess equipment conditions. These sensors collect data on various parameters such as temperature, vibration, and acoustics. The collected data is then analyzed using AI algorithms to detect anomalies and predict future breakdowns. For example, a manufacturing plant using AI can identify unusual vibration patterns in a motor, signaling the need for maintenance before the motor fails. This proactive approach not only enhances equipment longevity but also contributes to energy savings and resource optimization.

A comprehensive approach to smart maintenance in sustainable manufacturing can be summarized in the following steps:

- Installation of smart sensors on critical equipment.

- Continuous data collection and real-time monitoring.

- Use of AI algorithms to analyze data and predict maintenance needs.

- Timely intervention to prevent equipment failure.

- Regular updates and recalibration of AI models based on new data.

Furthermore, the integration of AI in maintenance strategies supports eco-friendly practices by reducing waste associated with equipment disposal. The following table highlights the environmental benefits achieved through AI-enabled smart maintenance:

| Benefit | Description |

|---|---|

| Reduced Waste | Minimizes the disposal of equipment by extending its usable life. |

| Energy Efficiency | Optimizes energy consumption by ensuring equipment operates at peak efficiency. |

| Resource Conservation | Decreases the need for raw materials by reducing equipment turnover. |

AI and Circular Economy Initiatives

The integration of AI technologies into circular economy initiatives presents a transformative opportunity for sustainable manufacturing. By leveraging AI’s capabilities, businesses can optimize resource utilization and minimize waste, fundamentally altering traditional production models. AI algorithms can analyze complex datasets to identify patterns and predict material lifecycle, thus enabling manufacturers to make informed decisions about resource recovery and recycling processes. The implementation of AI-driven insights can lead to a significant reduction in raw material consumption, ultimately fostering a more sustainable industrial ecosystem.

Key Benefits of AI in Circular Economy:

- Enhanced Resource Efficiency: AI systems can track and manage resources with precision, ensuring that materials are used optimally and waste is minimized.

- Improved Product Lifecycle Management: By predicting product degradation and maintenance needs, AI helps extend the lifecycle of products, promoting reuse and remanufacturing.

- Better Waste Sorting and Recycling: AI-powered sorting technologies can efficiently separate materials, increasing the quality and quantity of recyclables.

Moreover, AI facilitates the creation of innovative business models that align with circular economy principles. For instance, predictive analytics can support the shift from ownership to service-based models, where products are leased rather than sold, thus enhancing product stewardship and recycling efforts. Such models not only reduce environmental impact but also open new revenue streams for companies willing to adapt their operations to sustainable practices.

To illustrate the impact of AI on circular economy initiatives, consider the following data presented in the table below:

| AI Application | Impact on Circular Economy |

|---|---|

| Resource Optimization | Reduces material waste by 30% |

| Predictive Maintenance | Extends product lifespan by 20% |

| AI-Driven Recycling | Improves recycling efficiency by 25% |

In conclusion, AI’s role in advancing circular economy initiatives is pivotal for achieving sustainable manufacturing goals. By enhancing resource efficiency, extending product lifecycles, and improving recycling processes, AI transforms manufacturing from a linear to a circular model, paving the way for a greener future.

AI-Powered Quality Control

AI-powered quality control is at the forefront of transforming sustainable manufacturing processes. By leveraging advanced algorithms and machine learning techniques, manufacturers can achieve unprecedented levels of precision and accuracy in detecting defects and inconsistencies in products. This not only ensures higher quality standards but also significantly reduces material waste, as early detection of defects allows for immediate corrective actions.

One of the most significant advantages of AI in quality control is its ability to process vast amounts of data in real-time. This capability enables manufacturers to perform comprehensive inspections at high speeds without compromising accuracy. For instance, AI systems can analyze thousands of images per minute, identifying even the most minute defects that might be missed by human inspectors. This level of scrutiny guarantees that only products meeting the highest standards reach consumers, thereby minimizing returns and waste.

AI-powered quality control systems also contribute to sustainability by optimizing resource use. By ensuring that materials and energy are not wasted on defective products, manufacturers can significantly reduce their environmental footprint. Moreover, these systems can be integrated with predictive maintenance tools, which further enhance sustainability by anticipating equipment failures and reducing downtime. This integration ensures machinery operates at peak efficiency, conserving energy and resources.

To illustrate the impact of AI-powered quality control, consider the following data visualization:

| Quality Control Method | Defect Detection Rate | Material Waste Reduction |

|---|---|---|

| Traditional Inspection | 85% | 10% |

| AI-Powered Inspection | 99% | 25% |

This table highlights the superior efficiency of AI-powered systems over traditional methods in both detecting defects and reducing material waste, underscoring their vital role in promoting sustainable manufacturing practices.

Enhancing Worker Safety with AI

Artificial Intelligence (AI) is playing a pivotal role in enhancing worker safety within the manufacturing sector. By leveraging advanced technologies, AI systems can predict potential hazards, monitor working conditions, and ensure compliance with safety regulations. This proactive approach not only minimizes the risk of accidents but also fosters a safer work environment for employees.

One of the key applications of AI in worker safety is the use of wearable devices equipped with sensors. These devices can track various parameters such as heart rate, body temperature, and movement patterns. By analyzing this data in real-time, AI algorithms can detect signs of fatigue or stress, alerting workers and supervisors to take necessary precautions. Furthermore, AI-powered cameras and drones are increasingly being used to monitor large facilities, identifying unsafe practices or hazardous conditions.

- Real-time monitoring of environmental conditions such as air quality and noise levels.

- Predictive maintenance of machinery to prevent malfunctions and accidents.

- Automated reporting and documentation of safety incidents for continuous improvement.

In addition to these applications, AI is also being used to train workers more effectively. Virtual reality (VR) and augmented reality (AR) technologies, combined with AI, provide immersive training experiences that prepare workers for real-life scenarios without exposure to actual danger. This not only enhances their skills but also boosts their confidence in handling complex machinery and emergency situations.

| AI Tools | Function | Impact on Safety |

|---|---|---|

| Wearable Sensors | Monitor vital signs and motion | Prevents overexertion and accidents |

| AI-Powered Cameras | Surveillance and hazard detection | Identifies unsafe practices |

| VR/AR Training | Simulates real-life scenarios | Enhances skill and confidence |

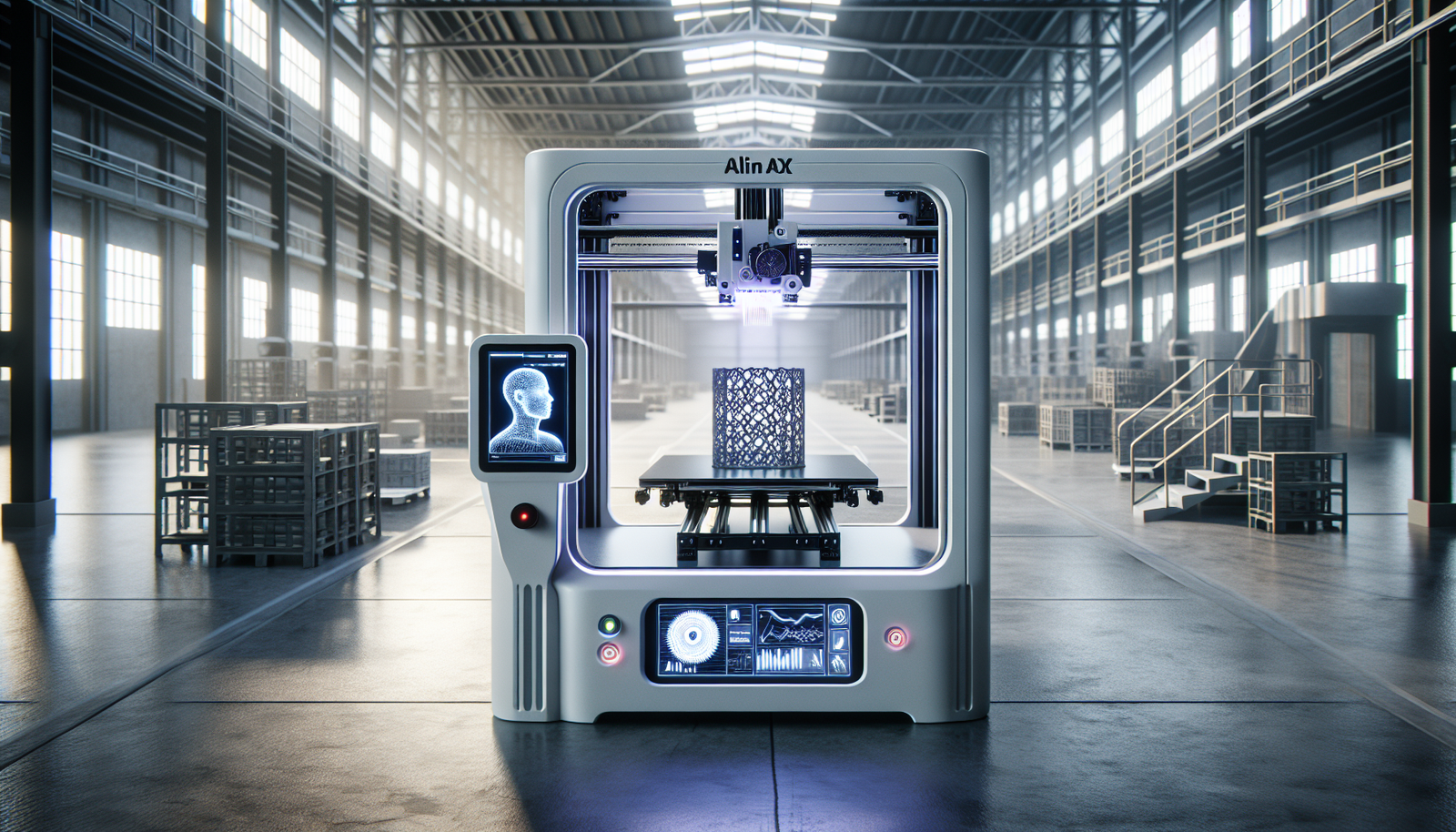

AI in Sustainable Product Design

Artificial Intelligence (AI) is playing a pivotal role in the evolution of sustainable product design, empowering industries to innovate while minimizing environmental impact. By leveraging AI-driven tools, designers can create products that are not only efficient but also environmentally friendly. AI algorithms analyze vast amounts of data to identify materials and processes that reduce waste and energy consumption. This approach ensures that products are designed with sustainability as a core principle, ultimately leading to a reduction in the carbon footprint of manufacturing activities.

One of the significant advantages of using AI in product design is its ability to optimize the use of resources. AI systems can simulate various design scenarios and predict their environmental impact. This allows designers to choose the most sustainable options from the outset. For instance, AI can suggest alternative materials that are biodegradable or recycled, which significantly reduces the dependency on non-renewable resources. As a result, companies can produce goods that are not only cost-effective but also eco-friendly, catering to the growing consumer demand for sustainable products.

| AI Application | Benefits |

|---|---|

| Material Selection | Reduces waste and promotes the use of recycled materials |

| Design Optimization | Enhances product efficiency and lowers energy consumption |

Furthermore, AI facilitates the integration of eco-friendly practices throughout the product lifecycle. By employing machine learning algorithms, manufacturers can forecast the environmental impact of their products over time, enabling them to make informed decisions during the design phase. This proactive approach helps in identifying potential sustainability issues early, allowing for adjustments before mass production begins. As a result, the integration of AI in sustainable product design not only supports environmental goals but also drives innovation, ultimately leading to a greener future for the manufacturing industry.

AI’s Impact on Water Conservation

Artificial Intelligence is playing a pivotal role in revolutionizing water conservation practices within the manufacturing sector. By integrating AI technologies, manufacturers can optimize water usage and significantly reduce wastage. AI algorithms analyze vast amounts of data from various stages of the manufacturing process, identifying areas where water consumption can be minimized. This is achieved through predictive analytics that forecast water needs and adjust usage accordingly, ensuring that water is utilized efficiently and sustainably.

One of the most significant contributions of AI to water conservation is its ability to detect leaks and inefficiencies in real-time. Smart sensors and AI-driven monitoring systems can quickly identify leaks in pipelines and machinery, allowing for immediate repairs and preventing unnecessary water loss. Furthermore, AI systems can provide insights into usage patterns, helping manufacturers to implement strategies that further reduce water consumption.

AI also facilitates water recycling and reuse within manufacturing processes. By employing machine learning models, manufacturers can predict the quality of wastewater and determine the best treatment methods to make it reusable. This not only conserves water but also reduces the environmental impact by minimizing the release of pollutants into natural water bodies.

| AI Application | Impact on Water Conservation |

|---|---|

| Leak Detection | Real-time identification and repair of leaks, reducing water wastage. |

| Usage Optimization | Predictive analytics to adjust water usage according to needs. |

| Water Recycling | Improved treatment methods for reusing wastewater. |

In conclusion, AI’s integration into sustainable manufacturing processes marks a significant step forward in water conservation efforts. By harnessing the power of AI, manufacturers not only enhance their operational efficiency but also contribute to a more sustainable and eco-friendly future.

The Future of AI in Eco-Friendly Practices

The integration of Artificial Intelligence in eco-friendly practices is poised to revolutionize the landscape of sustainable manufacturing. As industries strive to minimize their environmental impact, AI technologies are being harnessed to create smarter and more efficient systems. Predictive analytics is one such AI-driven tool that is transforming how manufacturers approach sustainability. By analyzing vast amounts of data, predictive analytics can forecast potential equipment failures, optimize resource usage, and significantly reduce waste. This not only conserves natural resources but also leads to substantial cost savings.

Another promising application of AI in sustainable manufacturing is the enhancement of energy efficiency. AI algorithms can monitor energy consumption patterns in real-time, identifying areas where energy is being wasted. By implementing AI-driven energy management systems, manufacturers can achieve substantial reductions in energy use. For instance, factories equipped with AI systems have reported up to a 20% decrease in energy consumption, contributing to a significant reduction in carbon emissions. This is a critical step forward in the quest for carbon-neutral manufacturing processes.

Furthermore, AI is playing a crucial role in the development of circular economy models. By using machine learning algorithms, manufacturers can design products with their entire lifecycle in mind, from production to disposal. This involves utilizing recycled materials, designing for easy disassembly, and facilitating the reuse of components. AI aids in optimizing these processes, ensuring minimal waste generation and promoting resource efficiency. The implementation of AI in circular economy practices not only supports environmental goals but also offers economic advantages by reducing material costs and creating new market opportunities.

In summary, the future of AI in eco-friendly practices holds immense potential for driving sustainable manufacturing forward. By leveraging AI technologies, industries can enhance their operational efficiency, reduce environmental impact, and foster innovation in sustainable practices. As these technologies continue to evolve, they will undoubtedly play a pivotal role in shaping a greener and more sustainable future for manufacturing across the globe.